The Tool You’ve Been Looking For

A modern layout optimization program built for packaging.

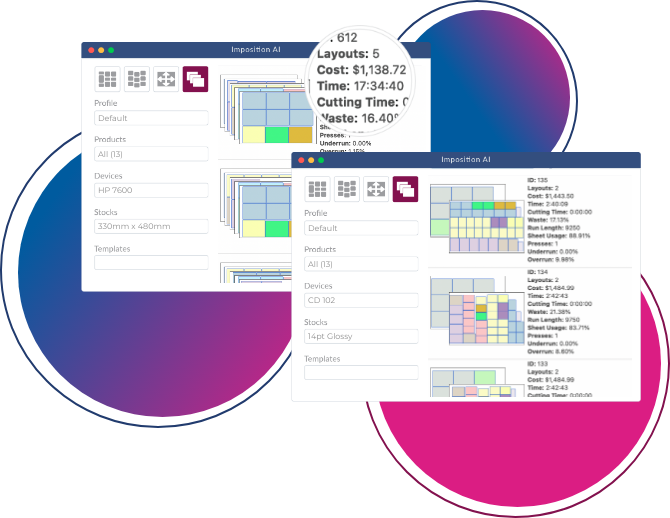

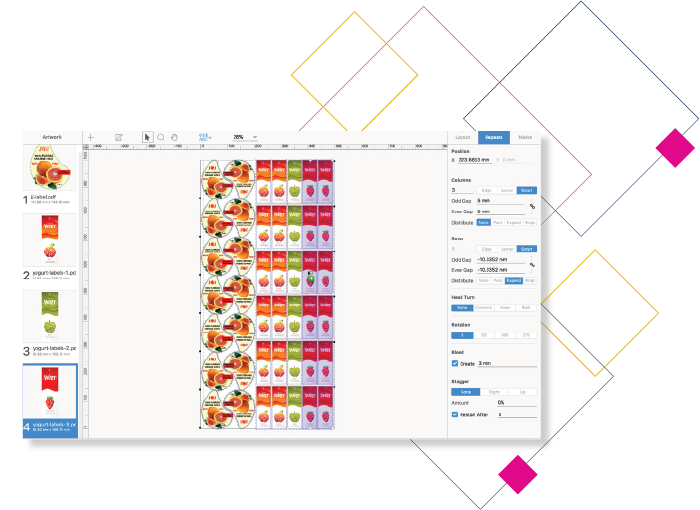

Intelligent Distribution

Tilia Phoenix uses a powerful, dynamic imposition calculation to quickly determine the best distribution of orders to maximize each press run.

You make the rules

Model your production environment inside of tilia Phoenix. Set-up your presses, stocks, marks, and finishing equipment then let Imposition A.I. do the rest.

Simple drag & drop interface

No more clunky software designed in the 90’s. Tilia Phoenix is built on modern development stacks and it feels like it.

Out-of-the-box CSV integration

Quickly automate tilia Phoenix with data from your website or business system using CSV spreadsheets.

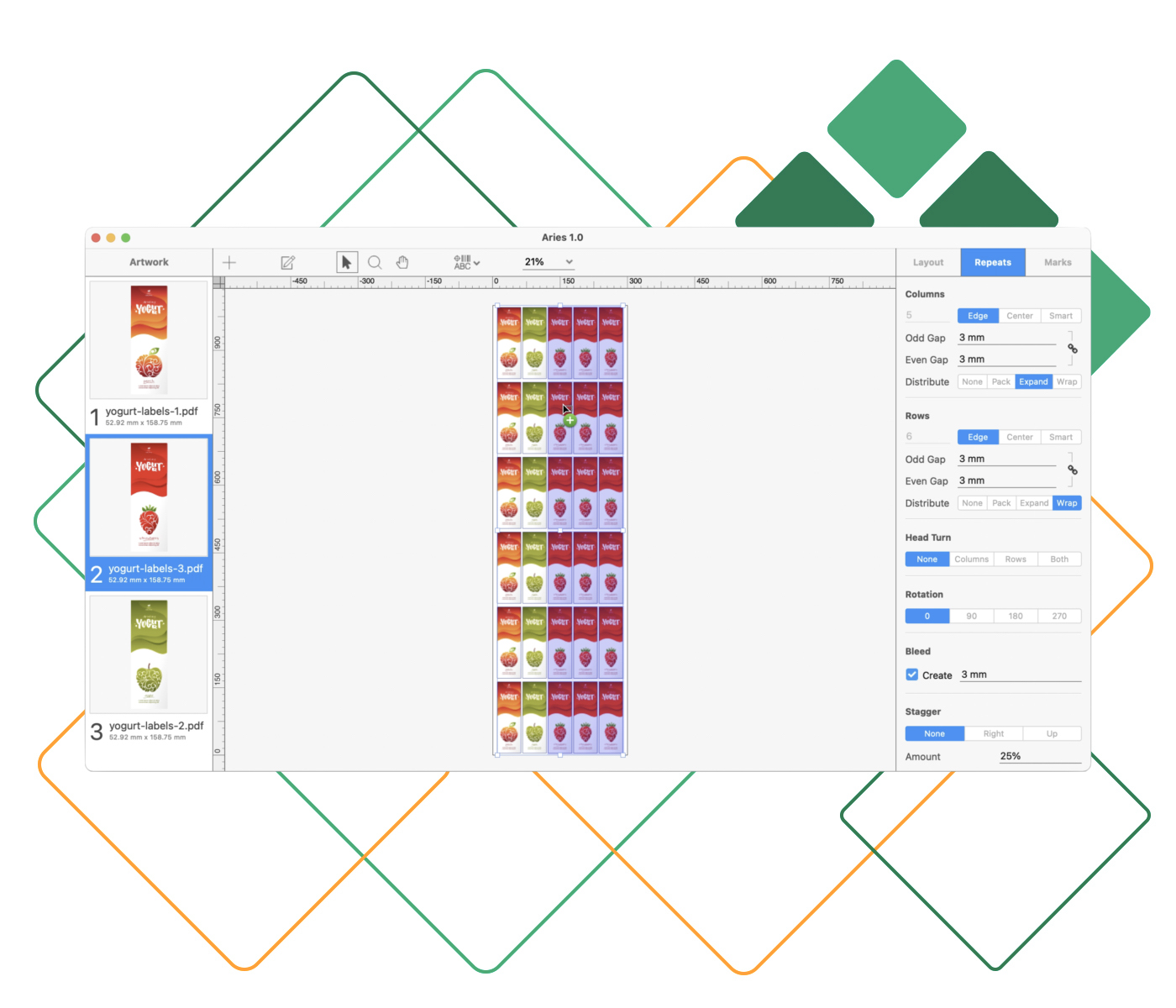

Nesting & CAD Based Prepress

Tilia Phoenix brings an all new approach to step-and-repeat with a simple drag-and-drop user interface.

Smart Mark Technology

Decorate your layouts with industry standard production marks. Add your own custom PDF or Scriptable marks for additional data transformation.

An Intelligent Tooling Library

No need to remake a die ever again. Tilia Phoenix uses shape-detection to create a smart library.

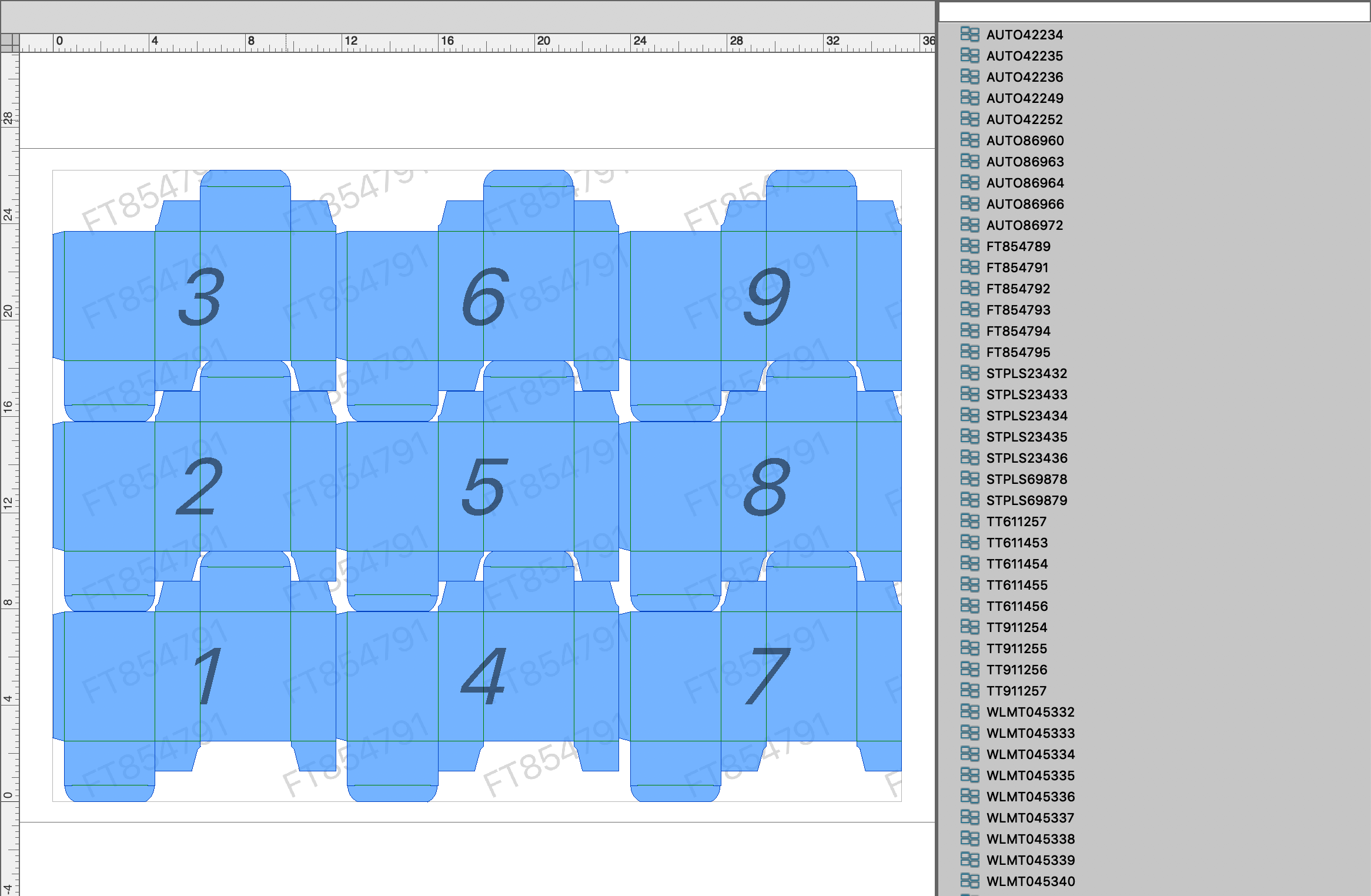

Import Structural Designs

Import CF2, PDF, or DXF file formats to ensure flawless automated plate layouts. Preserve step-and repeat parameters, sheet and board sizes, and varnish areas.

Die-based masking for graphics

Define non-printing areas and mask-out unwanted areas of a design file. Adjust overlapping graphic masks intelligently and apply once to the entire layout.

Station numbering

Insert a placeholder for the Station Number that specifies attributes such as position, font, size, and the inks in which the number is to be printed.

Plan Faster & Smarter with Imposition A.I.

Reduce press changeover and makeready with smarter production layouts. Let tilia Phoenix enable your team to create faster and smarter combination calculations.

Workflow Integration

With so many ways to integrate, tilia Phoenix fits seamlessly into every packaging workflow solution. Integrations available via JDF, hotfolder, and REST API just to name a few.

Lane Optimization for Digital Label Printing

Teaming up with the leading digital press manufacturers, Tilia Labs has created smart lane optimization to help reduce material and ink waste by as much as 25%.

Short-Run Order Batching

Reduce clicks and material by batching and ganging common items into their own lanes or changing items mid-lane.

Click-Based & Coverage-Based Ink Costing

Break down the cost of a digital job with an advanced analysis of inks. Estimate ink cost with accuracy whether your device is coverage-based or click-based.