Is Shallow Work Crushing Your Margins?

There is no doubt that your staff is your most valuable resource. Every printer has access to the same hardware, software, services, and support. Your staff, their experience, and the way they hustle to do jobs right and on time are what sets you apart. However, how you manage your staff and automation can dramatically impact their performance and your bottom line.

So, how do you manage to get the most out of your employees? In his book, Deep Work: Rules for focused success in a distracted world[1], Cal Newport, associate professor of computer science at Georgetown University, described the difference between deep and shallow work. He defines the term “deep work” as “professional activities performed in a state of distraction-free concentration that push your cognitive capabilities to their limit. These efforts create new value, improve your skill, and are hard to replicate.” In contrast, Cal describes “shallow work” as “non-cognitive, logistical” tasks often performed while distracted. He gives examples such as opening emails, phone interruptions, social media interactions, and online searches. Shallow work is not only an inefficient use of talented employee time; it also reduces their ability to perform deep work due to distracting interruptions.

Look around your shop, and you’ll see valuable employees performing shallow work everywhere. For example, every time someone manually processes a file, they take a minute to open the ticket, determine what to do, find the file, and open it. When prepress workers finish starting a task, they will take another 30 seconds to close it, save it, and inform the next person in line. An average $55/hr budgeted hourly rate would add roughly $1.50 to every job for every prepress touch before anything is done! Add in 8 minutes for a graphic artist to imposition a sheet of business cards with crop marks and color bars, and you’ve subtracted nearly nine dollars from your profit margin for that one manual operation. And those 8 minutes could quickly become 20 if your graphic artist is attempting to nest varied-sized and shaped objects.

Professor Newport has numerous suggestions and books on shifting the balance from shallow to deep work in an organization. He discusses organization, planning, time dedication, social media breaks, and other ideas in his blog (www.calnewport.com/blog/); however, print service providers and in-plants have additional opportunities: Automation of menial and repetitious work.

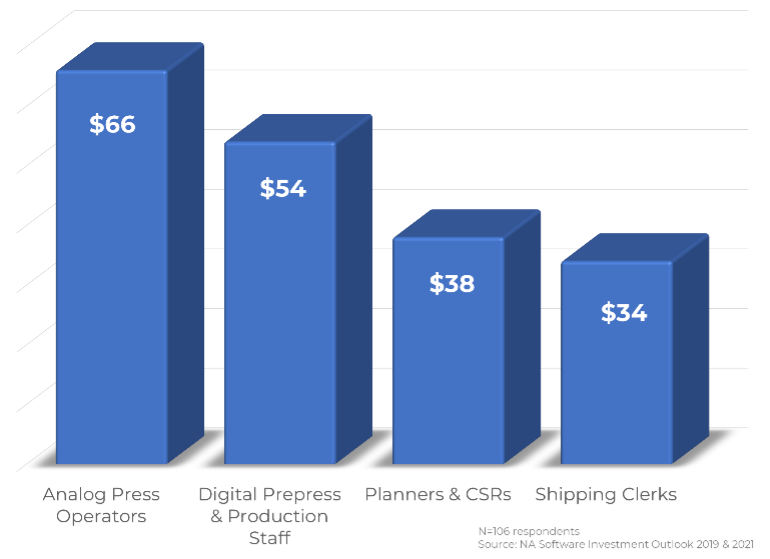

Typical PSP Salaries

Proper Automation Use Is Needed to Boost Profits

The above chart contains Keypoint Intelligence survey information from 2019 and 2021, but labor rates are skyrocketing. Paper prices are also continuously increasing. And resource availability of both staff and paper is increasingly challenging. This new situation means that automation, which was once a nice idea, is critical to remain profitable.

For years, vendors have tried to justify automation ROI by simply translating labor savings into dollars. This thinking rarely pans out because printers can’t save money by eliminating 10 percent of one position and 5 percent of another. However, that changes in an era of labor shortages, where people handle multiple jobs. Today’s automation benefits are not derived from reducing headcount.

- Automation can reduce the need to hire additional staff.

- It can reduce overtime costs in short-staffed operations.

- It can provide stability by never getting sick, quitting, or demanding a salary increase.

- It enables staff to spend more time performing deep work with less of the distracting interruptions of shallow work, which improves employee morale and increases productivity.

- And it lets you maximize the uplift of your most valuable resource, your staff, by taking over menial and redundant tasks and allowing people to add actual value.

Achieve Maximum Uplift with Intelligent Planning

Tilia Labs’ intelligent planning software helps PSPs optimize production by better managing the influx of smaller jobs while reducing the avalanche of shallow work that typically arrives with it. The range of planning and intelligent imposition solutions from Tilia Labs ensures you are getting the best use of your equipment, substrates, and labor costs—whether you offer commercial, label, folding carton, or wide format printing.

The software’s Imposition AI understands the mix of jobs, looks across all available printing methods and calculates thousands of potential production layouts in seconds, not hours. Select the best plan based on costs, waste, service level agreement (SLAs), and your overall production schedule

Intelligent planning and imposition are critical for getting out of the small-job slowdown and reaching maximum velocity in your printing operations.

[1] NEWPORT, C. A. L. (2018). Deep work: Rules for focused success in a distracted world. GRAND CENTRAL PUB.

Author: Greg Cholmondeley is the Director of Keypoint Intelligence’s Production Workflow Consulting Service, which helps vendors define their future through consulting, market analysis, research, and forecasting. He also works directly with print service providers to improve their operations through workflow audits based on workflow journey mapping and the five stages of smart print manufacturing.